Table of Content

When comparing an MCP and a circuit breaker, the key difference lies in their specific use and protection features. An MCP (Motor Circuit Protector) is designed mainly to protect motors from short circuits, while a standard circuit breaker offers broader protection, including overload and short circuit protection for various electrical devices. This makes MCPs specialized devices mostly used in motor control environments.

Circuit breakers are more versatile and can be found in many settings beyond motor protection. They respond to overloads, short circuits, and sometimes ground faults, making them essential for overall electrical safety in homes and industries. MCPs, on the other hand, often need additional components to guard against motor overload, but excel at handling motor-specific faults quickly.

Understanding these differences helps in selecting the right device for your needs. Whether protecting motors or general circuitry, choosing correctly impacts the reliability and safety of electrical systems.

Understanding Circuit Breakers and MCPs

Circuit breakers and motor circuit protectors (MCPs) both serve to protect electrical circuits but are designed for different purposes. Each device has specific features that make it suitable for particular applications, especially when dealing with motors versus general electrical circuits.

What Is a Circuit Breaker?

A circuit breaker is a safety device that automatically interrupts electrical flow in a circuit when it detects an overload or short circuit. It protects wiring and connected equipment from damage caused by excess current. Circuit breakers are widely used in residential, commercial, and industrial settings.

There are various types of circuit breakers, including miniature circuit breakers (MCBs), molded case circuit breakers (MCCBs), and specialty breakers like arc-fault and ground-fault circuit interrupters. Circuit breakers can protect against several electrical hazards, such as overcurrent, short circuits, and ground faults. They reset automatically or manually once the fault is cleared.

What Is a Motor Circuit Protector (MCP)?

A motor circuit protector (MCP) is a specialized type of circuit breaker. Its main role is to protect motors from short circuits and electrical faults. MCPs are often called instantaneous trip (IT) breakers because they trip quickly when the current exceeds a certain level.

Unlike standard circuit breakers, MCPs usually do not provide overload protection. Instead, they need other devices, like thermal overload relays, to protect the motor from overheating due to extended overload conditions. MCPs are commonly found in motor control centers and help improve motor-related circuit safety by isolating faults rapidly.

Key Functional Differences

The primary difference between a circuit breaker and an MCP lies in their protection scope. Circuit breakers provide broad protection against overloads, short circuits, and ground faults for various types of electrical circuits.

MCPs focus mainly on short circuit protection for motors and trip instantly to prevent damage. They lack built-in overload protection, which limits their use to motor-specific applications where other overload safeguards are present.

| Feature | Circuit Breaker | Motor Circuit Protector (MCP) |

| Overload Protection | Yes | Typically No |

| Short Circuit Protection | Yes | Yes |

| Application | General circuits | Motor circuits |

| Trip Speed | Standard | Instantaneous |

| Common Environment | Homes, offices, factories | Motor control centers and motor starters |

Tripping Mechanisms and Protection Features

Different circuit protection devices use specific tripping methods to respond to electrical faults like overloads and short circuits. These mechanisms define how quickly and reliably a device reacts, ensuring safety and preventing damage.

Thermal Element and Overload Protection

The thermal element in a circuit breaker detects overloads by reacting to heat generated by excess current. When current exceeds the rated level for a period, the thermal part heats up and bends a bimetallic strip. This mechanical action trips the breaker, stopping the current flow.

Overload protection is essential to prevent motors and circuits from sustained high currents that cause damage. Many standard circuit breakers include this thermal overload protection. Motor Circuit Protectors (MCPs) sometimes lack built-in overload protection, relying on external devices like thermal overload relays for this function.

Thermal elements respond slowly compared to magnetic trips, allowing short surges but acting on prolonged overloads to avoid nuisance tripping.

Magnetic Trip and Instantaneous Trip

Magnetic trip mechanisms respond instantly to short circuits by detecting sudden high currents. They use an electromagnet that quickly moves a trip lever when current spikes, cutting power immediately. This rapid action protects wiring and devices from severe damage.

MCPs often use an instantaneous trip feature focused solely on short-circuit protection. This magnetic trip reacts without delay but usually does not protect against overloads.

Standard circuit breakers combine magnetic trip with thermal elements for broader protection, covering both short circuits and overloads. MCPs depend on this magnetic trip but may require complementary devices to handle overload conditions.

Current Ratings and Sensitivity

Current ratings set the maximum current a breaker or protector can carry safely. MCPs are designed to handle a wide amperage range for motor circuits—from very low currents to hundreds of amps.

Sensitivity differs by device type. Standard breakers adjust to protect against overloads and short circuits at varying levels. MCPs prioritize short-circuit sensitivity, reacting swiftly to instantaneous faults but sometimes less equipped for gradual overloads.

Choosing the correct device depends on the motor’s full load amperage and expected electrical conditions. Ratings typically include a margin (about 25% higher than actual load) to prevent false trips during normal operation.

Physical Design, Standards, and Applications

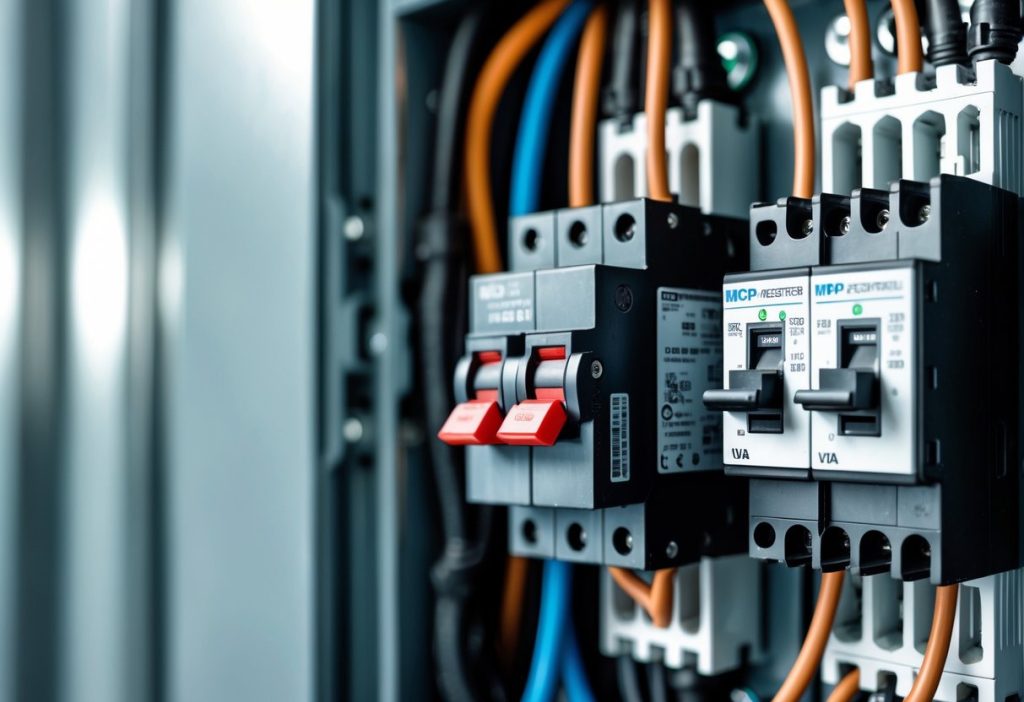

Motor circuit protectors (MCPs) and standard circuit breakers differ in their physical design, certification standards, and how they are used in electrical systems. These differences affect where and how each device is installed, especially in motor control setups. Key aspects include size, UL certification, and integration into motor starters.

Physical Design and Size

MCPs are designed specifically for protecting motors and typically have a compact, modular design. They can be smaller than many standard circuit breakers because they focus on short-circuit protection rather than broad overload protection.

Standard circuit breakers come in various sizes and designs. These include miniature circuit breakers (MCBs), molded case circuit breakers (MCCBs), and other forms. Their size varies depending on the current rating and the protection features they include.

The design of MCPs often allows easier installation within motor starters or motor control centers. They may have specific terminals and mounting styles optimized for motor circuit protection.

UL Listing vs UL Recognized

UL Listing and UL Recognized are two certification marks indicating safety standards compliance but differ in scope.

UL Listed products meet full safety and performance standards for end-use applications. Standard circuit breakers often have UL Listed status, meaning they are tested for standalone use in various settings.

UL Recognized components are evaluated for use as part of a larger system rather than sold separately. MCPs frequently have UL Recognized status since they are designed to be part of motor starters or control panels, not standalone devices.

This difference is important for compliance and installation, as UL Recognized products must be verified within the overall system’s safety.

Application in Motor Starters

MCPs are commonly installed inside motor starters, where they provide short-circuit protection for motors. They work alongside overload relays, which protect against excess current over time. This setup ensures motors receive focused and layered protection.

Standard circuit breakers can be used for general circuit protection but are less specialized for motor applications. While some circuit breakers include overload protection, they are not optimized for the specific electrical conditions motors create, such as high starting currents.

Motor starters are built to house MCPs because these protectors fit neatly and work efficiently with the other control components, supporting motor safety and control.

Premium electrical and automation equipment

When it comes to electrical and automation equipment, quality is essential. Premium products provide enhanced safety, reliability, and performance. They help prevent hazards that can arise from using lower-quality devices.

Key Features of Premium Equipment:

- Safety Standards: Premium equipment often meets or exceeds international safety standards, ensuring it operates safely and efficiently.

- Durability: Quality materials and robust construction lead to longer lifespans, reducing the need for frequent replacements.

- Performance: High-end devices generally offer better efficiency, which can lead to lower energy costs and improved output.

Investing in premium equipment can significantly reduce risks. For instance, safety features are built-in to prevent electrical faults. Additionally, reputable brands provide proper certifications and guidelines, assuring users of their safety.

Examples of Premium Equipment Providers:

- Gabby Electric: Known for its extensive range of electrical products, Gabby Electric emphasizes quality and safety. Their offerings include automation solutions designed for various industries.

Benefits of Choosing Premium Brands:

- Peace of mind knowing safety is prioritized.

- Better support and warranty options.

- Access to the latest technology and innovations.

Purchasing premium electrical and automation equipment can enhance safety and performance while minimizing the risks associated with lower-quality products.